|

|

||

|---|---|---|

| clients | ||

| dev | ||

| dxf | ||

| hardware | ||

| img | ||

| ino | ||

| notes | ||

| scad | ||

| scripts | ||

| stl | ||

| .gitignore | ||

| .gitmodules | ||

| LICENSE | ||

| README.md | ||

| VERSION.txt | ||

| models.txt | ||

README.md

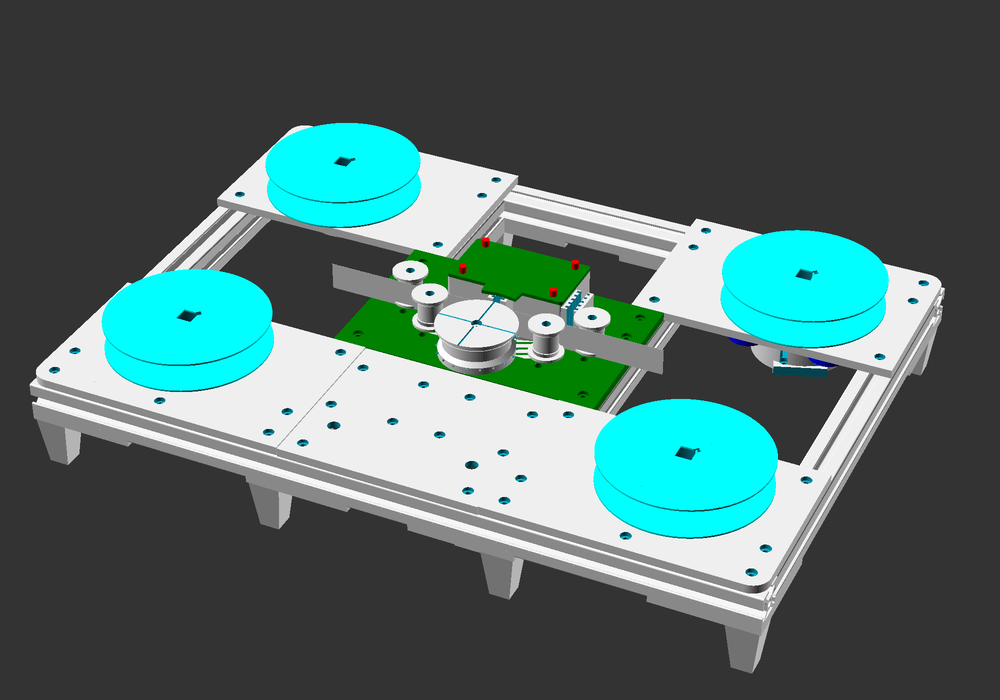

contact printer

A desktop 16mm contact printer and film transport platform made using 3D printing and aluminum extrusion.

Project Home: git.sixteenmillimeter.com/16mm/contact_printer

Acknowledgements

Developed with support from Filmwerkplaats at WORM and SPECTRAL.

Special thanks to Esther Urlus, Hrvoje Spudić and Nan Wang.

Magnetic clutch design inspired by Clyde Shaffer's Shaffer Linear Processor.

Description

This contact printer is designed to make 16mm prints using affordable electronics and 3D printing. It is not intended as a replacement for professional printers like the Bell & Howell Model C. This project is for DIY filmmakers, independent artists and small film labs to have a machine that can produce reasonable-quality work prints with a small footprint on short lengths of film easily.

Bill of Materials

Below are estimates based on per-unit costs found online. Actual price of a full build may be higher.

| Part | Qty | Cost (USD) |

|---|---|---|

| M4 hex bolt 40mm | 4 | 5.0 |

| M3 sliding t slot nut | 25 | 1.5 |

| M3 hex cap bolt 8mm | 25 | 2.25 |

| M3 hex cap bolt 6mm | 8 | 0.56 |

| L298N Motor driver module | 1 | 2.89 |

| ESP32 GPIO breakout board | 1 | 5.99 |

| ESP32 Dev board | 1 | 6.66 |

| 250RPM DC geared motor | 2 | 29.98 |

| 2020 Aluminum extrusion 420mm | 2 | 5.22 |

| 2020 Aluminum extrusion 260mm | 4 | 6.44 |

| 100RPM DC geared motor with encoder | 1 | 17.02 |

| --------- | --------------- | ------------------------------------ |

| TOTAL | 74 | 83.51 |